Product Description

Product Description

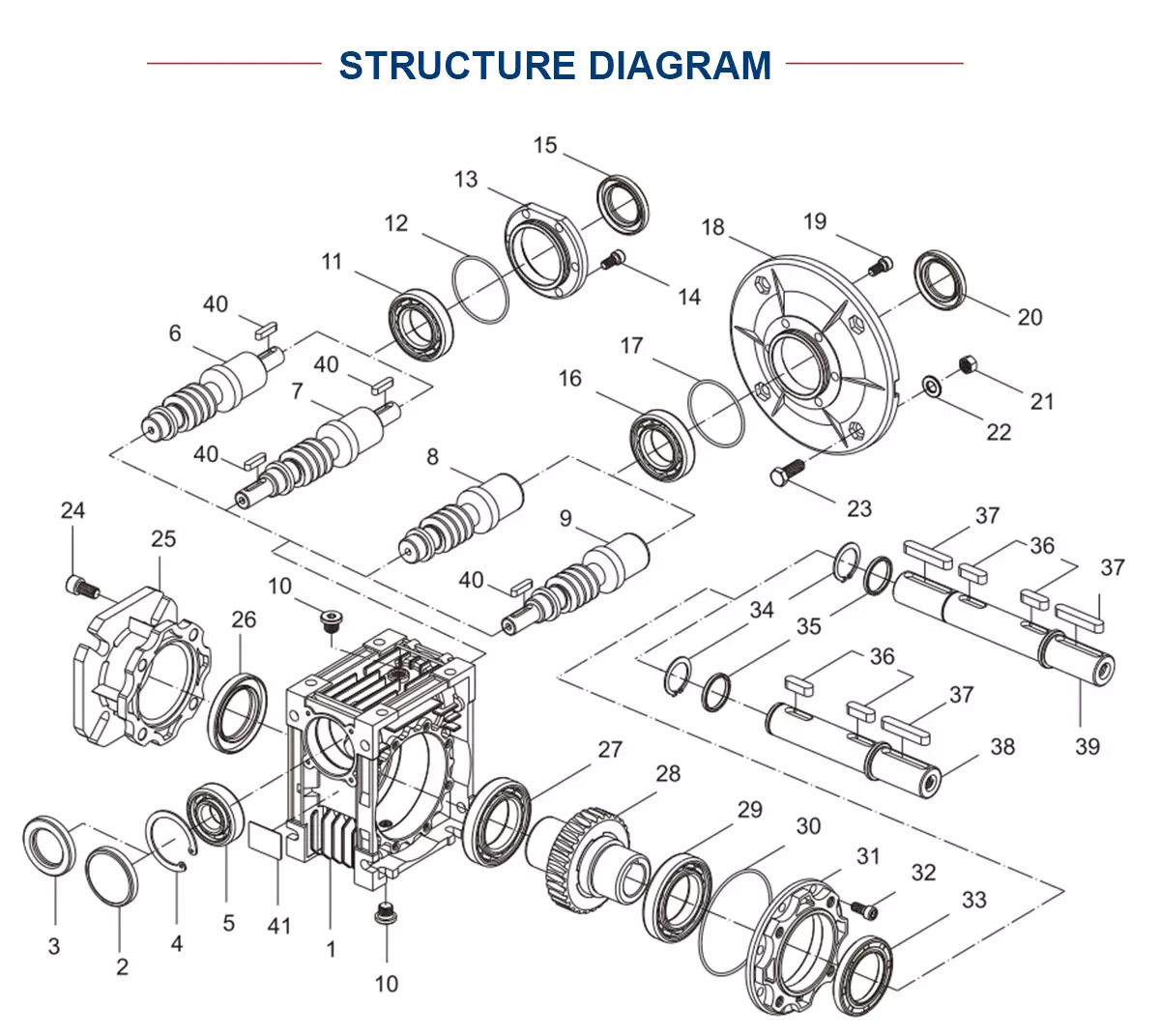

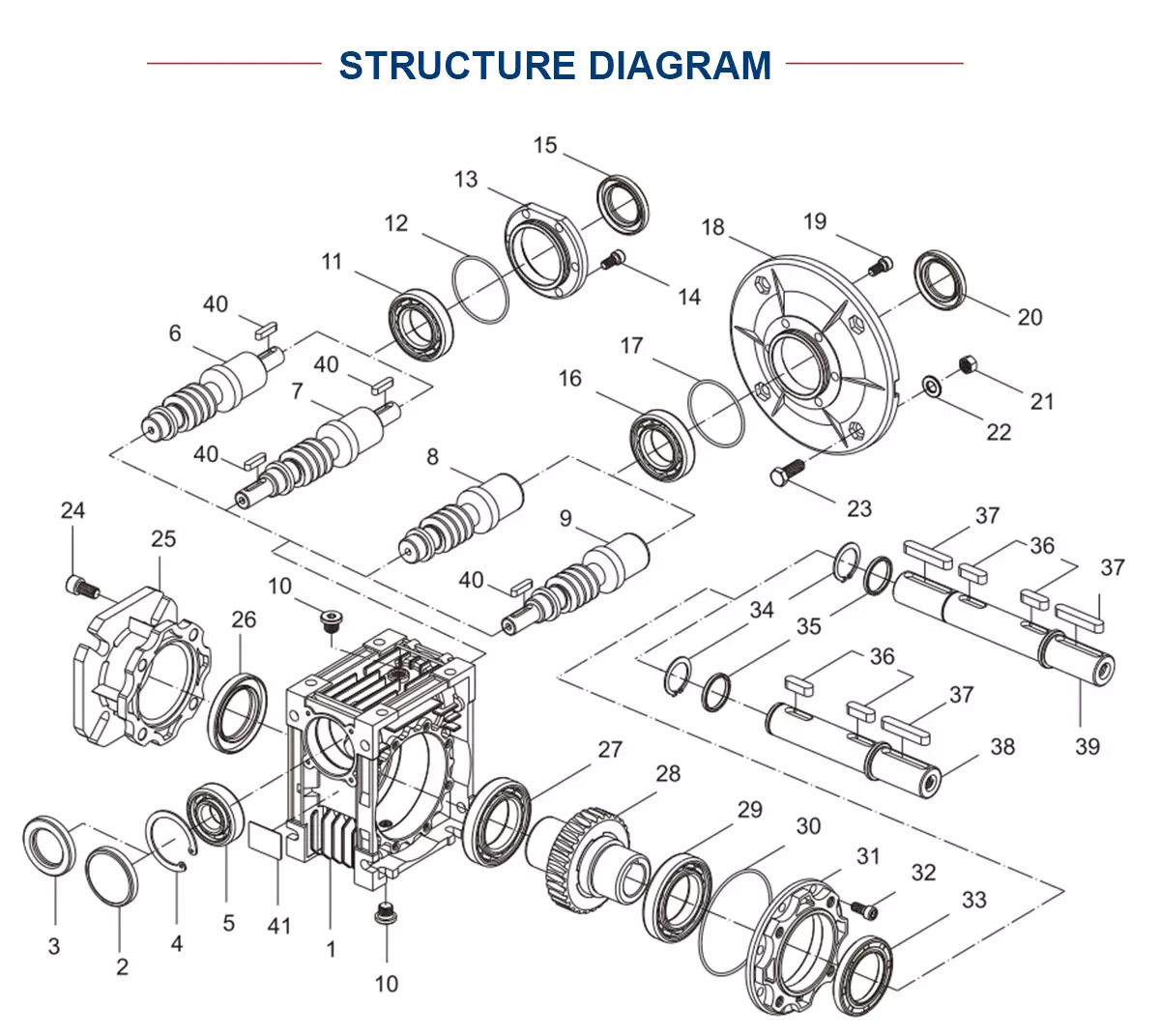

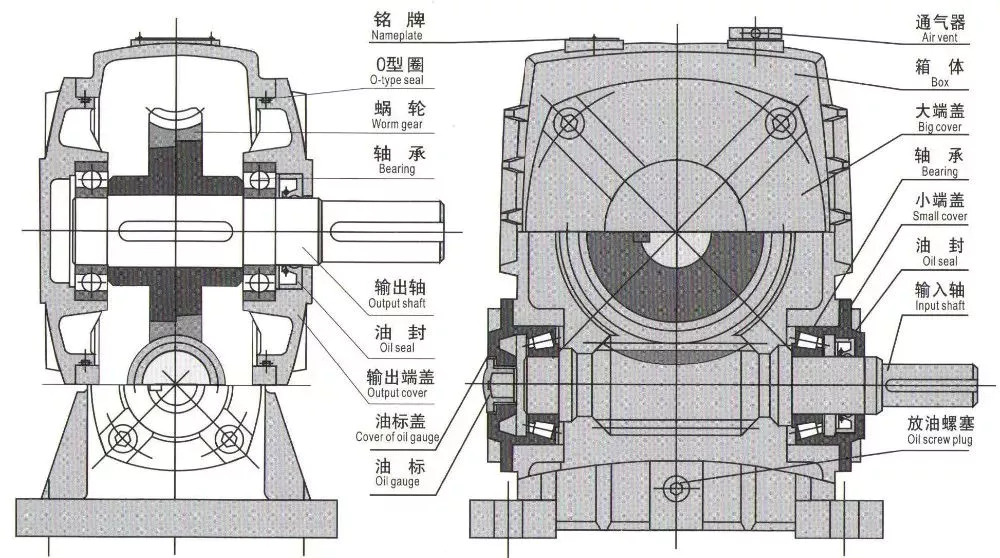

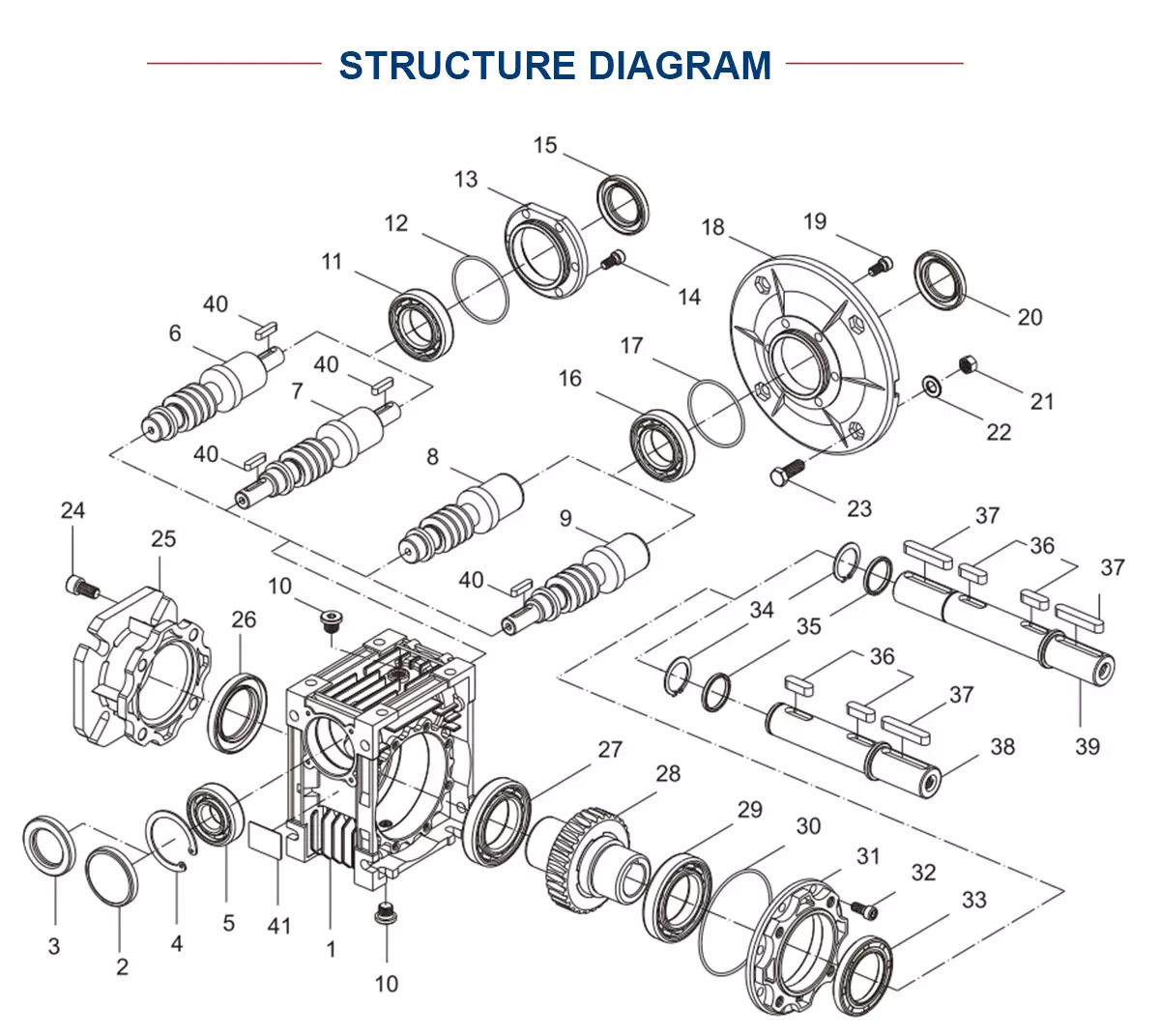

Slewing drive is a full cycle rotary reduction transmission mechanism that integrates a driving power source. It uses a rotary bearing as the driving follower and mechanism attachment, and attaches an active component, driving source, and cover to 1 of the inner and outer rings of the rotary bearing. The other ring is used as both the driving follower and the connecting base of the driven working component. This makes use of the characteristic that the rotary bearing itself is a full cycle rotary connection, Efficiently configuring the driving power source and main transmission components, making it a universal deceleration transmission mechanism that integrates rotation, deceleration, and driving functions, while also having a simple structure and easy manufacturing and maintenance.

Product Parameters

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 3 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 77:1 | Reduction ratio | i | – | 62:1 | |

| Raceway diameter | Do | mm | 162 | Raceway diameter | Do | mm | 222.5 | |

| Overturning moment | M | N.m | 13600 | Overturning moment | M | N.m | 26300 | |

| Torque | Ma | N.m | 1500 | Torque | Ma | N.m | 3850 | |

| Weight | W | Kg | 25 | Weight | W | Kg | 59 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 3 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 62:1 | Reduction ratio | i | – | 83:1 | |

| Raceway diameter | Do | mm | 224 | Raceway diameter | Do | mm | 315 | |

| Overturning moment | M | N.m | 26300 | Overturning moment | M | N.m | 51800 | |

| Torque | Ma | N.m | 3850 | Torque | Ma | N.m | 8100 | |

| Weight | W | Kg | 59 | Weight | W | Kg | 85 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 5 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 88:1 | Reduction ratio | i | – | 88:1 | |

| Raceway diameter | Do | mm | 335 | Raceway diameter | Do | mm | 342.5 | |

| Overturning moment | M | N.m | 75100 | Overturning moment | M | N.m | 67800 | |

| Torque | Ma | N.m | 8600 | Torque | Ma | N.m | 8600 | |

| Weight | W | Kg | 93 | Weight | W | Kg | 87 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 5 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 106:1 | Reduction ratio | i | – | 106:1 | |

| Raceway diameter | Do | mm | 422.5 | Raceway diameter | Do | mm | 425 | |

| Overturning moment | M | N.m | 131500 | Overturning moment | M | N.m | 132600 | |

| Torque | Ma | N.m | 12800 | Torque | Ma | N.m | 12800 | |

| Weight | W | Kg | 119 | Weight | W | Kg | 121 |

Company Profile

HangZhou solarich machinery Co., Ltd. is a professional manufacturer of bearings, We can design and manufacture single-row ball slewing bearings, double-row ball slewing bearings, three-row roller slewing bearings, ball combination slewing bearings, crossed roller bearings, crossed tapered roller bearings Bearings, slewing drives and custom bearings.

The company has 1 of the earliest group of R & D, design and manufacturing personnel who apply slewing drive to various mechanical products. In construction machinery, we have experienced rich practice and accumulated valuable experience in the application of slewing drive in engineering machinery, mining machinery, agricultural machinery, and specialized vehicles.

Adhering to the business philosophy of “Quality and Integrity”, we will continue to provide excellent bearings and high-quality services to serve global customer.

Solutions

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

|---|---|

| Step: | Single-Step |

| Layout: | Three-Ring |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the costs associated with installing and maintaining gear drives?

The installation and maintenance of gear drives involve various costs. Here’s a detailed explanation:

1. Initial Installation Costs:

– The initial installation costs include the purchase of gear drives and any additional components required for installation.

– The cost of gear drives can vary depending on factors such as gear type, size, quality, and manufacturer.

– Additional installation costs may include materials, labor, equipment, and any necessary modifications to the existing machinery or systems.

2. Maintenance and Inspection Costs:

– Regular maintenance and inspection are essential for ensuring the optimal performance and longevity of gear drives.

– Maintenance costs may include expenses related to lubrication, cleaning, and adjustments.

– Inspection costs can involve the use of specialized tools, equipment, or professional services to assess gear drive conditions and identify any potential issues.

3. Replacement and Repair Costs:

– Over time, gear drives may experience wear, damage, or failure, requiring replacement or repair.

– Replacement costs involve the purchase of new gear drives or specific components, such as gears or bearings.

– Repair costs may include labor, replacement parts, or the engagement of specialized repair services.

4. Downtime and Production Losses:

– Gear drive maintenance or replacement activities can result in downtime, leading to production losses.

– Downtime costs can vary depending on the industry, production rates, and the criticality of the gear drive in the overall operation.

– Minimizing downtime through efficient maintenance planning and scheduling can help mitigate production losses.

5. Training and Expertise:

– Proper maintenance of gear drives may require trained personnel with specific knowledge and expertise.

– Costs associated with training programs, certifications, or hiring skilled maintenance technicians should be considered.

– In some cases, companies may choose to outsource gear drive maintenance to specialized service providers, incurring additional costs.

6. Lifecycle Costs:

– Gear drives have a finite lifespan, and considering their lifecycle costs is essential.

– This includes the cumulative costs associated with installation, maintenance, repairs, replacements, and eventual decommissioning or disposal.

– Evaluating the lifecycle costs helps in making informed decisions regarding gear drive selection, maintenance strategies, and overall cost-effectiveness.

It’s important to note that the costs associated with installing and maintaining gear drives can vary significantly depending on factors such as the complexity of the system, the size and type of gear drives, the operating conditions, and the specific industry requirements. Implementing proactive maintenance practices, adhering to manufacturer recommendations, and monitoring gear drive performance can help optimize costs and maximize the operational efficiency and reliability of gear drive systems.

How are gear drives used in renewable energy applications?

Gear drives play a crucial role in various renewable energy applications. Here’s a detailed explanation:

1. Wind Turbines:

– Gear drives are widely used in wind turbines to convert the low-speed rotation of the turbine blades into high-speed rotation suitable for generating electricity.

– The gear drives amplify the rotational speed, allowing the generator to operate at the required speed to produce electricity efficiently.

2. Solar Tracking Systems:

– In solar tracking systems, gear drives are employed to adjust the position of solar panels or mirrors to maximize the capture of solar energy.

– The gear drives enable precise and controlled movement of the panels or mirrors, aligning them with the sun’s position throughout the day for optimal energy collection.

3. Hydroelectric Power Plants:

– Gear drives are utilized in hydroelectric power plants to convert the slow rotational motion of the turbine into high-speed rotation for power generation.

– The gear drives increase the rotational speed and transmit the power to the generator, which converts the mechanical energy into electrical energy.

4. Tidal and Wave Energy Converters:

– Gear drives are employed in tidal and wave energy converters to increase the rotational speed of the turbine or generator system.

– They help convert the relatively slow and irregular motion of the tides or waves into a higher-speed rotation suitable for electricity generation.

5. Geothermal Power Plants:

– Gear drives are utilized in geothermal power plants to transmit power from the geothermal turbine to the generator for electricity production.

– They enable the conversion of the low-speed, high-torque rotational motion of the turbine into high-speed rotation required by the generator.

6. Biomass Energy Systems:

– Gear drives are used in biomass energy systems to convert the rotational motion of the biomass combustion engine or steam turbine into high-speed rotation for electricity generation.

– The gear drives help optimize the rotational speed and torque characteristics of the system for efficient power production.

Overall, gear drives are essential components in renewable energy applications, enabling the efficient conversion of various natural energy sources into usable electricity. They help amplify rotational speed, adjust positions for optimal energy capture, and transmit power from turbines to generators. By facilitating the effective utilization of renewable energy sources, gear drives contribute to the growth and sustainability of clean and renewable energy generation.

How do you choose the right gear drive for a specific application?

Choosing the right gear drive for a specific application requires careful consideration of various factors. Here’s a detailed explanation of the key considerations in selecting the appropriate gear drive:

1. Load Requirements:

– Determine the magnitude and type of the load the gear drive will need to transmit.

– Consider factors such as torque, speed, and any shock or impact loads.

– Select a gear drive with the load capacity and durability to handle the specific load requirements.

2. Speed and Torque Requirements:

– Analyze the desired speed and torque characteristics of the application.

– Consider the required speed reduction or increase and the torque multiplication or reduction.

– Choose a gear drive with the appropriate gear ratio to achieve the desired speed and torque output.

3. Space Constraints:

– Evaluate the available space for installing the gear drive.

– Consider the dimensions and configuration of the gear drive, including the shaft orientation and mounting options.

– Select a gear drive that fits within the space limitations without compromising performance or accessibility.

4. Efficiency:

– Assess the desired efficiency and energy requirements of the application.

– Different types of gear drives have different levels of efficiency.

– Consider the efficiency of the gear drive and balance it with other performance factors.

5. Noise and Vibration:

– Evaluate the noise and vibration limitations of the application.

– Some gear drives, such as helical gears, offer quieter and smoother operation compared to others.

– Consider the noise and vibration characteristics of the gear drive to ensure it meets the application’s requirements.

6. Maintenance and Reliability:

– Consider the desired maintenance schedule and reliability expectations.

– Evaluate factors such as lubrication requirements, maintenance access, and expected lifespan.

– Choose a gear drive that aligns with the maintenance and reliability goals of the application.

7. Cost:

– Assess the budget constraints and cost-effectiveness of the gear drive.

– Consider the initial investment cost, maintenance costs, and potential savings in energy efficiency.

– Select a gear drive that provides the best balance between performance and cost for the specific application.

By carefully considering these factors and understanding the specific requirements of the application, it becomes possible to choose the right gear drive that meets the performance, space, efficiency, reliability, and budget needs. Consulting with gear drive manufacturers or industry experts can also provide valuable guidance in the selection process.

editor by Dream 2024-05-16

China supplier Solar Tracker Slewing Drive Gear Motor bevel gear set

Product Description

CHINAMFG Drive SC9 slewing drive gear motor worm gear for 18-32 square meter solar tracker system.

Slewing drive motor for single and dual axis solar plant,PV and CSP system.

|

Model |

SC9 |

IP |

IP65 |

|

Brand |

Coresun Drive |

Available Load Weight |

500-800kg |

|

IP Class |

IP65 |

Output Torque |

854N.m |

|

Tilting Moment Torque |

33.9KN.m |

Holding Torque |

38.7KN.m |

|

Mounting Bolts |

M16 |

Electrial Motor |

24VDC |

|

Gear Ratio |

61:1 |

Efficiency |

40% |

Coresun Drive Equipment HangZhou Co., Ltd. Slewing drives function with standard worm technology, in which the worm on the horizontal shaft acts as the driver for the gear. The rotation of the horizontal screw turns a gear about an axis perpendicular to the screw axis. This combination reduces the speed of the driven member and also multiplies its torque; increasing it proportionally as the speed decreases. The speed ratio of shafts depends CHINAMFG the relation of the number of threads on the worm to the number of teeth in the worm wheel or gear.

Coresun Slewing Drive movement can reduce power consumption, since the security role. In addition to the field of use in the daily solar power systems are usually used for Special vehicle, heavy-duty flat-panel truck, container cranes, truck mounted crane, automobile crane and aerial vehicles, cranes, gantry cranes, small wind power stations, space communications, satellite receiver, etc…The Slewing Drive in the solar photovoltaic industry, the general configuration DC planetary reduction motor or AC geared motors; Main configuration of the hydraulic motor as a power-driven construction machinery

Coresun Slewing Drive principle of the large transmission ratio of the deceleration device to transmit motion and power between the 2 axes staggered in space. The Slewing Drive transmission is usually the case of the main components of the worm and wheel bearings, shell, and the power source

Slewing drive is a special bearing. And a slewing drive usually consist of slewing bearing, worm shaft, housing, bearing, motor and so on. Motor drive the worm shaft, the outer ring of slewing bearing will rotate, the outer ring output the torque through flange while the inner ring of slewing bearing is fixed in housing.Coresun Slewing Drive and rotary products, compared with the ease of installation, ease of maintenance, Installation space savings advantages to a greater extent.

Slewing drives are widely used in aerospace area, solar power systems, wind turbines, satellite broadcasting system, and engineering machinery like truck cranes, and man lifts, etc. Recently years, it has been prosperously used in photovoltaic power generation systems, special vehicle, heavy-duty flat-panel truck, container cranes, truck mounted crane, automobile crane and aerial vehicles, cranes, gantry cranes, small wind power stations, space communications, satellite receiver, etc.

Why Choose Us:

Solar heliostat tracking system is a mechanical and electronic control unit system which optimizes the use of sunlight to improve photoelectric conversion efficiency in the process of photothermal and photovoltaic power generation. It mainly includes photovoltaic applications and photothermal applications.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

6. Delivery Time: 7 days after

7. Warranty Time: 5 years

8. ISO and CE certificate for quality guarantee

Coresun Drive Slewing Drive Motor Production Photo and Application

CHINAMFG Drive processes the metallography detection to check the material and organization structure of worm shaft,slewing gear and casting housing.

Coresun Drive testing reports for slewing bearing,worm shaft and finished slewing drive

CONTACT US

It is sincerely looking CHINAMFG to cooperating with you for and providing you the best quality product & service with all of our heart!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO, CE |

| Application: | Industrial |

| Specification: | Normal, SC9-61-RC-24H15300-RV. A |

| Holding Torque: | 38.7kn.M |

| Tilting Moment Torque: | 33.9kn.M |

| Customization: |

Available

| Customized Request |

|---|

How do gear drives work in robotic and automated systems?

Gear drives play a crucial role in robotic and automated systems by transmitting motion and power between different components. Here’s a detailed explanation of how gear drives work in these systems:

1. Power Transmission:

– In robotic and automated systems, gear drives are used to transmit power from motors to various mechanical components.

– Electric motors provide rotational motion, which is converted into linear or angular motion by the gear drive.

– The gear drive consists of a set of gears with different sizes and configurations that mesh together to transfer torque and speed.

2. Speed and Torque Conversion:

– Gear drives allow for the conversion of speed and torque between the motor and the driven components.

– By using gears with different sizes (varying number of teeth), the gear drive can change the rotational speed and torque output.

– For example, a gear drive with a larger gear driving a smaller gear will increase the torque while reducing the speed, and vice versa.

3. Motion Control:

– Gear drives enable precise motion control in robotic and automated systems.

– By selecting the appropriate gear ratio, the gear drive can control the speed and position of the driven components.

– Gear drives can be used to achieve smooth and accurate movements, such as in robot arms, conveyor systems, or CNC machines.

4. Reducing Inertia:

– Inertia refers to an object’s resistance to changes in motion.

– Gear drives can help reduce the overall inertia in robotic and automated systems.

– By using smaller gears, the gear drive can reduce the inertia of the driven components, allowing for faster and more responsive movements.

5. Backlash Compensation:

– Backlash refers to the slight play or clearance between gear teeth, which can result in a loss of accuracy and precision.

– Gear drives in robotic and automated systems often incorporate backlash compensation mechanisms to minimize this issue.

– These mechanisms can include preloading the gears or using anti-backlash gears to eliminate or reduce the effects of backlash.

6. Load Distribution:

– In complex robotic systems, multiple gear drives are often used to distribute the load and share the torque among different components.

– This distribution of load helps prevent overloading of individual gear drives and ensures a balanced operation of the system.

7. Redundancy:

– Some robotic and automated systems incorporate redundant gear drives to enhance reliability and fault tolerance.

– Redundant gear drives can provide backup functionality in case of failure or allow for continued operation with reduced performance in the event of a single gear drive failure.

Overall, gear drives are essential components in robotic and automated systems, enabling power transmission, motion control, speed and torque conversion, and load distribution. The specific design and configuration of gear drives in these systems depend on the application requirements, desired performance, and system constraints.

How are gear drives used in renewable energy applications?

Gear drives play a crucial role in various renewable energy applications. Here’s a detailed explanation:

1. Wind Turbines:

– Gear drives are widely used in wind turbines to convert the low-speed rotation of the turbine blades into high-speed rotation suitable for generating electricity.

– The gear drives amplify the rotational speed, allowing the generator to operate at the required speed to produce electricity efficiently.

2. Solar Tracking Systems:

– In solar tracking systems, gear drives are employed to adjust the position of solar panels or mirrors to maximize the capture of solar energy.

– The gear drives enable precise and controlled movement of the panels or mirrors, aligning them with the sun’s position throughout the day for optimal energy collection.

3. Hydroelectric Power Plants:

– Gear drives are utilized in hydroelectric power plants to convert the slow rotational motion of the turbine into high-speed rotation for power generation.

– The gear drives increase the rotational speed and transmit the power to the generator, which converts the mechanical energy into electrical energy.

4. Tidal and Wave Energy Converters:

– Gear drives are employed in tidal and wave energy converters to increase the rotational speed of the turbine or generator system.

– They help convert the relatively slow and irregular motion of the tides or waves into a higher-speed rotation suitable for electricity generation.

5. Geothermal Power Plants:

– Gear drives are utilized in geothermal power plants to transmit power from the geothermal turbine to the generator for electricity production.

– They enable the conversion of the low-speed, high-torque rotational motion of the turbine into high-speed rotation required by the generator.

6. Biomass Energy Systems:

– Gear drives are used in biomass energy systems to convert the rotational motion of the biomass combustion engine or steam turbine into high-speed rotation for electricity generation.

– The gear drives help optimize the rotational speed and torque characteristics of the system for efficient power production.

Overall, gear drives are essential components in renewable energy applications, enabling the efficient conversion of various natural energy sources into usable electricity. They help amplify rotational speed, adjust positions for optimal energy capture, and transmit power from turbines to generators. By facilitating the effective utilization of renewable energy sources, gear drives contribute to the growth and sustainability of clean and renewable energy generation.

How do you calculate the gear ratio in a gear drive?

Calculating the gear ratio in a gear drive involves determining the relationship between the number of teeth on the driving gear (pinion) and the number of teeth on the driven gear. Here’s a detailed explanation:

The gear ratio is defined as the ratio of the number of teeth on the driven gear to the number of teeth on the driving gear. It represents the speed or torque multiplication or reduction achieved by the gear drive.

The gear ratio (GR) can be calculated using the following formula:

GR = Number of teeth on driven gear / Number of teeth on driving gear

For example, consider a gear drive with a driving gear (pinion) having 20 teeth and a driven gear having 60 teeth. The gear ratio can be calculated as follows:

GR = 60 (driven gear) / 20 (driving gear) = 3

In this case, the gear ratio is 3:1, indicating that for every three revolutions of the driving gear, the driven gear completes one revolution. This represents a speed reduction, with the driven gear rotating at one-third the speed of the driving gear.

It’s important to note that the gear ratio can be expressed in different formats, such as a decimal, fraction, or as a ratio. The choice of representation depends on the specific requirements and conventions of the gear drive application.

Additionally, it’s worth mentioning that gear drives can have multiple gears arranged in series or parallel, forming gear trains. In such cases, the overall gear ratio is calculated by multiplying the individual gear ratios of each gear pair in the train.

When designing or selecting gear drives, calculating the gear ratio is essential for determining the speed reduction or increase and torque amplification provided by the gear system. It enables engineers and designers to match the gear drive to the desired operational requirements of the mechanical system.

editor by Dream 2024-05-16

China high quality Dual Axis Solar Tracker Slewing Drive Gear Motor bevel spiral gear

Product Description

SVH3 dual axis slewing drive slewing bearing is available to 3-10 square meter solar tracker system

|

Model |

SVH3 |

Place of Origin |

HangZhou,China |

|

Brand |

Coresun Drive |

Type |

Dual Axis |

|

IP Class |

IP65 |

Output Torque |

446N.m |

|

Tilting Moment Torque |

1100N.m |

Holding Torque |

2000N.m |

|

Mounting Bolts |

M10 |

Output Speed |

1rpm |

|

Gear Ratio |

62:1 |

Efficiency |

40% |

Coresun Drive is a professional manufacturer and exporter of slewing bearing/slewing ring/slew circle, slewing drives/slew drive, which are mainly applied in port machinery, mining machinery, welding machinery, construction vehicles, modular vehicles, single or dual axis solar tracking systems, and small wind power systems etc.

The slewing drive is a new type of slewing product, usually called slewing ring, which is usually composed of worm, slewing ring, housing, motor and other components. Since the core components are slewing bearings, they can simultaneously withstand axial forces, radial forces, and overturning moments. Compared with traditional rotary products, the new slewing drive features easy installation, easy maintenance and a greater degree of installation space.

Slewing drive are widely used in PV,CPV,STP solar tracking systems and construction applications including truck cranes, manlifts, turntables, port machinery, modular vehicles, small wind power systems and satellite communications.

Product Advantage:

Slew drives are ready-to-mount modules which are capable of transmitting forces and high torques. CHINAMFG Drive slew drives consist of a ball bearing and a worm screw enclosed by a housing structure.

The enclosed housing guarantees a sustainable, low-maintenance operation without loss of lubrication, as well as protection against environmental influences.

1-3m Dia.TVRO dish dual axis slewing drive slewing gear

Higher tracking precision

IP class 65

Temperature range: -30ºC-60ºC

High Transmission Efficiency

High impact resistance

SVH3 dual axis slewing drive slewing bearing is available to 3-10 square meter solar tracker system.

For 4-6pcs solar panels tracking design

For 1-2.5 Dia. satellite receiver and solar dish system

1, What are the differentiates between CHINAMFG with other supplier?

Profession and reliability.

Our advantages are multiple available technologies, strong quality assurance, and good at project & supply chain management.

2, Is there a cost for CHINAMFG service?

There is no additional cost above the product and tooling price except third party service.

3, Will I be able to visit the supplier myself?

First, all of our supply partner has undergone a series of screening and audit process, we can provide complete audit report to you.

Secondly, if you want to perform your own independent supplier audit procedure, our representatives can accompany and assistant with you to achieve it.

4, How to deal with the quality problem?

A. With our partners we perfom APQP at early stage in each project.

B. Our factory must fully understand the quality concerns from customers and implement product & process quality requirements.

C. Our quality professionals who perfom patrol inspection in our factories.

We perform final inspectors before the goods are packed.

D. We have 3rd party inspectors who perform final audit checks on the packed goods prior to dispatch from China.

5, Can you take responsibility for me?

Of course, I’m happy to help you! But I just take responsitility fo my products.

Please offer a test report.

If it was our fault, absolutely we can make a compensation for you, my friend!

6, Do you like to serve the client only with small order?

We enjoy to grow up together with all our clients whatever big or small.

Your will become bigger and bigger to be with us.

Dual Axis SVH3 Slewing Drive Production Photo

Coresun Drive processes the Slewing Drive Motor metallographic testing to ensure the quality of raw material and follows the standard inspection specification.

Certification of CE, ISO

CONTACT US

It is sincerely looking CHINAMFG to cooperating with you for and providing you the best quality product & service with all of our heart!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Holding Torque: | 1100n.M |

|---|---|

| Tilting Moment Torque: | 2200n.M |

| Output Torque: | 446n.M |

| Output Speed: | 1rpm |

| IP Class: | IP65 |

| Slef-Locking: | Yes |

| Customization: |

Available

| Customized Request |

|---|

How do gear drives handle heavy loads and high torque?

Gear drives are designed to handle heavy loads and high torque in various applications. Here’s a detailed explanation:

1. Gear Geometry:

– Gear drives utilize specific gear geometries to handle heavy loads and high torque.

– The shape and size of gear teeth, such as involute profiles, are optimized to distribute the load evenly across the gear face.

– Gear teeth are designed with appropriate strength and thickness to withstand the forces and torque applied during operation.

2. Material Selection:

– Gear drives are typically made from high-strength materials, such as hardened steel or alloy steels, to withstand heavy loads and high torque.

– These materials offer excellent mechanical properties, including high tensile strength, hardness, and fatigue resistance.

– The selection of appropriate materials ensures the gear drives can handle the required load and torque without deformation or failure.

3. Gear Size and Ratio:

– Gear drives can handle heavy loads and high torque by optimizing the gear size and gear ratio.

– Increasing the size of the gears, including the diameter and width of the gear teeth, enhances their load-carrying capacity.

– Choosing the appropriate gear ratio allows for torque multiplication, enabling the gear drive to handle higher torque requirements.

4. Lubrication and Cooling:

– Effective lubrication is crucial for gear drives to handle heavy loads and high torque.

– Lubricants reduce friction between gear teeth, minimizing wear and heat generation.

– Proper lubrication also helps dissipate heat, preventing excessive temperature rise that can affect gear performance and integrity.

5. Gear Tooth Profile and Tooth Contact:

– Gear drives employ specific tooth profiles, such as involute or helical gears, to optimize load distribution and tooth contact.

– These profiles ensure that the load is distributed across multiple teeth, reducing stress concentration on individual teeth.

– Additionally, gear drives may incorporate modifications, such as crowning or tip relief, to improve tooth contact and minimize edge loading.

6. Structural Reinforcements:

– In applications with exceptionally heavy loads and high torque, gear drives may incorporate structural reinforcements.

– Reinforcements, such as additional support bearings, rigid housings, or bracing, enhance the overall strength and rigidity of the gear drive system.

– These reinforcements help distribute the load and torque more effectively and prevent excessive deflection or misalignment.

By employing appropriate gear geometry, selecting high-strength materials, optimizing gear size and ratio, ensuring effective lubrication, and incorporating tooth profile enhancements and structural reinforcements, gear drives can handle heavy loads and high torque. These design considerations enable gear drives to reliably transmit power and withstand the demanding operating conditions in various industrial, automotive, and machinery applications.

Can gear drives be custom-made for specific machinery?

Yes, gear drives can be custom-made to suit the specific requirements of machinery. Here’s a detailed explanation:

1. Application-Specific Design:

– Gear drive manufacturers have the capability to design and manufacture custom gear drives tailored to specific machinery and applications.

– The design process involves considering factors such as torque requirements, speed ratios, space constraints, operating conditions, and load characteristics.

2. Gear Type and Configuration:

– Gear drives can be customized based on the specific gear types and configurations required for the machinery.

– Different gear types, such as spur gears, helical gears, bevel gears, and worm gears, can be selected based on the application’s needs.

– The arrangement and configuration of gears, including single-stage or multi-stage setups, can be customized to achieve the desired performance.

3. Gear Materials and Heat Treatment:

– Custom gear drives allow for the selection of appropriate gear materials based on factors such as strength, wear resistance, and operating temperature.

– Gear materials commonly used include alloy steels, stainless steels, cast iron, and non-ferrous metals.

– Heat treatment processes, such as carburizing, quenching, and tempering, can be applied to enhance the gear’s mechanical properties and durability.

4. Lubrication and Sealing:

– Custom gear drives can be designed to incorporate specific lubrication and sealing systems to suit the machinery’s operating conditions.

– Lubrication methods, such as splash lubrication, oil bath lubrication, or forced lubrication, can be customized based on the gear drive requirements.

– Sealing arrangements can be tailored to prevent ingress of contaminants and ensure proper lubricant retention.

5. Mounting and Integration:

– Custom gear drives can be designed to facilitate easy mounting and integration into the specific machinery.

– Mounting features, such as flanges, shaft configurations, and bolt patterns, can be customized to ensure proper alignment and connection.

6. Performance Optimization:

– Custom gear drives offer the opportunity to optimize performance by fine-tuning gear parameters.

– Gear tooth profiles, backlash allowances, and noise reduction measures can be tailored to meet the machinery’s performance and operational requirements.

By leveraging the expertise of gear drive manufacturers and their ability to customize various aspects of the gear drive system, machinery designers and manufacturers can obtain gear drives that are specifically tailored to their unique requirements. Custom-made gear drives ensure optimal performance, reliability, and compatibility with the machinery, thereby enhancing overall operational efficiency and effectiveness.

How do gear drives compare to belt drives in terms of efficiency?

When comparing gear drives to belt drives in terms of efficiency, there are some key differences to consider. Here’s a detailed explanation:

Gear Drives:

– Gear drives are known for their high mechanical efficiency.

– With proper lubrication and maintenance, gear drives can achieve efficiency levels above 90%.

– The efficiency of gear drives remains relatively constant regardless of the load or speed.

– They are capable of transmitting high torque levels efficiently.

– Gear drives are suitable for applications that require precise speed control and high torque transmission.

Belt Drives:

– Belt drives, on the other hand, have lower mechanical efficiency compared to gear drives.

– The efficiency of belt drives can vary depending on factors such as belt type, tension, and load conditions.

– On average, belt drives typically have efficiency levels ranging from 90% to 98%.

– Belt drives can experience energy losses due to belt slippage, bending resistance, and flexing.

– They are commonly used in applications where speed variation, shock absorption, or noise reduction is required.

– Belt drives are suitable for transmitting power over long distances and accommodating misalignment between shafts.

Overall, gear drives generally offer higher efficiency compared to belt drives. However, it’s important to note that the specific efficiency of a gear drive or belt drive can be influenced by factors such as design, condition, operating conditions, and maintenance practices. Therefore, it’s crucial to carefully consider the requirements of the application and select the drive system that best meets the desired efficiency, performance, and other operational considerations.

editor by Dream 2024-05-16

China manufacturer Stock Popular Helical Gear Single Worm Gear Reduction Drive Slew Drive Se475 Se710 Se808 cycle gear

Product Description

Product Description

Slewing drive is a full cycle rotary reduction transmission mechanism that integrates a driving power source. It uses a rotary bearing as the driving follower and mechanism attachment, and attaches an active component, driving source, and cover to 1 of the inner and outer rings of the rotary bearing. The other ring is used as both the driving follower and the connecting base of the driven working component. This makes use of the characteristic that the rotary bearing itself is a full cycle rotary connection, Efficiently configuring the driving power source and main transmission components, making it a universal deceleration transmission mechanism that integrates rotation, deceleration, and driving functions, while also having a simple structure and easy manufacturing and maintenance.

Product Parameters

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 3 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 106:1 | Reduction ratio | i | – | 122:1 | |

| Raceway diameter | Do | mm | 475 | Raceway diameter | Do | mm | 500 | |

| Overturning moment | M | N.m | 168000 | Overturning moment | M | N.m | 184500 | |

| Torque | Ma | N.m | 14100 | Torque | Ma | N.m | 14800 | |

| Weight | W | Kg | 121 | Weight | W | Kg | 169 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 5 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 126:1 | Reduction ratio | i | – | 152:1 | |

| Raceway diameter | Do | mm | 525.5 | Raceway diameter | Do | mm | 630 | |

| Overturning moment | M | N.m | 203000 | Overturning moment | M | N.m | 296000 | |

| Torque | Ma | N.m | 15300 | Torque | Ma | N.m | 18200 | |

| Weight | W | Kg | 190 | Weight | W | Kg | 216 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 6 | Module | m | mm | 6 | |

| Reduction ratio | i | – | 138:1 | Reduction ratio | i | – | 154:1 | |

| Raceway diameter | Do | mm | 710 | Raceway diameter | Do | mm | 808 | |

| Overturning moment | M | N.m | 380000 | Overturning moment | M | N.m | 488000 | |

| Torque | Ma | N.m | 16500 | Torque | Ma | N.m | 18000 | |

| Weight | W | Kg | 290 | Weight | W | Kg | 450 |

| Name | Code | Unit | Value | Name | Code | Unit | Value | |

| Module | m | mm | 5 | Module | m | mm | 5 | |

| Reduction ratio | i | – | 61:1 | Reduction ratio | i | – | 78:1 | |

| Raceway diameter | Do | mm | 222.5 | Raceway diameter | Do | mm | 312.5 | |

| Overturning moment | M | N.m | 25200 | Overturning moment | M | N.m | 51200 | |

| Torque | Ma | N.m | 6500 | Torque | Ma | N.m | 7500 | |

| Weight | W | Kg | 36 | Weight | W | Kg | 41 |

Company Profile

HangZhou solarich machinery Co., Ltd. is a professional manufacturer of bearings, We can design and manufacture single-row ball slewing bearings, double-row ball slewing bearings, three-row roller slewing bearings, ball combination slewing bearings, crossed roller bearings, crossed tapered roller bearings Bearings, slewing drives and custom bearings.

The company has 1 of the earliest group of R & D, design and manufacturing personnel who apply slewing drive to various mechanical products. In construction machinery, we have experienced rich practice and accumulated valuable experience in the application of slewing drive in engineering machinery, mining machinery, agricultural machinery, and specialized vehicles.

Adhering to the business philosophy of “Quality and Integrity”, we will continue to provide excellent bearings and high-quality services to serve global customer.

Solutions

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

|---|---|

| Step: | Single-Step |

| Layout: | Three-Ring |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety precautions should be taken when working with gear drives?

Working with gear drives requires adherence to specific safety precautions to ensure the well-being of individuals involved. Here’s a detailed explanation:

1. Personal Protective Equipment (PPE):

– Wear appropriate personal protective equipment, such as safety glasses or goggles, gloves, and close-toed shoes, to protect against potential hazards.

– Use hearing protection if working in close proximity to gear drives that produce excessive noise.

2. Lockout/Tagout:

– Implement lockout/tagout procedures to isolate and de-energize gear drives before performing maintenance or repair tasks.

– This ensures that the equipment cannot be accidentally energized, preventing potential injury from unexpected movement or activation.

3. Training and Familiarity:

– Ensure that personnel working with gear drives are adequately trained and familiar with the equipment’s operation and safety procedures.

– Provide training on proper use, maintenance, and potential risks associated with gear drives.

4. Risk Assessment:

– Conduct a thorough risk assessment of the work area and gear drives to identify potential hazards and implement appropriate control measures.

– Address issues such as pinch points, entanglement hazards, and potential for falling objects.

5. Proper Installation and Maintenance:

– Follow manufacturer guidelines for the installation, setup, and maintenance of gear drives.

– Regularly inspect gears, shafts, bearings, and lubrication systems for signs of wear, damage, or malfunction.

– Perform maintenance tasks only when the gear drive is de-energized and properly locked out.

6. Guarding and Enclosures:

– Install appropriate guards and enclosures around gear drives to prevent accidental contact with moving parts.

– Ensure that guards are securely in place and not removed or bypassed during operation.

7. Proper Lifting and Handling:

– Use proper lifting techniques and equipment when moving or installing gear drives.

– Gear drives can be heavy and require mechanical means, such as cranes or forklifts, for safe handling.

8. Reporting and Addressing Safety Concerns:

– Encourage a culture of reporting and addressing safety concerns related to gear drives.

– Promptly address any identified safety issues or incidents to prevent future accidents.

It is essential to remember that these safety precautions serve as general guidelines, and specific precautions may vary depending on the type and size of the gear drives and the working environment. Always refer to the manufacturer’s instructions and consult with relevant safety professionals to ensure compliance with specific safety requirements.

What is the role of gear drives in automotive transmissions?

Gear drives play a crucial role in automotive transmissions. Here’s a detailed explanation:

1. Speed and Torque Conversion:

– Automotive transmissions use gear drives to convert the engine’s rotational speed and torque into the appropriate output for the wheels.

– By selecting different gear ratios, gear drives enable the transmission to adjust the speed and torque delivered to the wheels based on driving conditions and desired performance.

2. Gear Shifting:

– Gear drives facilitate gear shifting, allowing the driver to select different gear ratios to match the vehicle’s speed and load requirements.

– Depending on the transmission type (manual or automatic), gear drives are responsible for engaging and disengaging the gears during gear shifting operations.

3. Power Transmission:

– Gear drives transmit power from the engine to the wheels, enabling the vehicle to move.

– They transfer torque from the engine’s crankshaft to the transmission output shaft, which is connected to the wheels through the drivetrain.

4. Forward and Reverse Operation:

– Gear drives in automotive transmissions allow the vehicle to move both forward and backward.

– By engaging different gear combinations, the transmission can reverse the direction of power flow, enabling the vehicle to go in reverse.

5. Gear Reduction and Overdrive:

– Gear drives in transmissions provide gear reduction or overdrive capabilities.

– Gear reduction allows the engine to operate at higher RPMs while reducing the output speed, providing more torque for climbing steep inclines or towing heavy loads.

– Overdrive gears, on the other hand, allow the engine to operate at lower RPMs, reducing fuel consumption and engine wear during highway cruising.

6. Synchronizing and Noise Reduction:

– In manual transmissions, gear drives incorporate synchronizer mechanisms to facilitate smooth gear engagements and minimize gear clash.

– These synchronizers match the speeds of the gears before engagement, reducing wear on the gear teeth and enhancing shifting comfort.

– Gear drives can also incorporate noise reduction measures, such as helical or hypoid gears, to minimize gear noise and vibration during operation.

Overall, gear drives in automotive transmissions are essential for speed and torque conversion, gear shifting, power transmission, and enabling the vehicle to move in both forward and reverse directions. They provide the necessary mechanical advantage and flexibility to optimize engine performance, fuel efficiency, and driving dynamics, making them a fundamental component in the operation of automobiles.

How do you calculate the gear ratio in a gear drive?

Calculating the gear ratio in a gear drive involves determining the relationship between the number of teeth on the driving gear (pinion) and the number of teeth on the driven gear. Here’s a detailed explanation:

The gear ratio is defined as the ratio of the number of teeth on the driven gear to the number of teeth on the driving gear. It represents the speed or torque multiplication or reduction achieved by the gear drive.

The gear ratio (GR) can be calculated using the following formula:

GR = Number of teeth on driven gear / Number of teeth on driving gear

For example, consider a gear drive with a driving gear (pinion) having 20 teeth and a driven gear having 60 teeth. The gear ratio can be calculated as follows:

GR = 60 (driven gear) / 20 (driving gear) = 3

In this case, the gear ratio is 3:1, indicating that for every three revolutions of the driving gear, the driven gear completes one revolution. This represents a speed reduction, with the driven gear rotating at one-third the speed of the driving gear.

It’s important to note that the gear ratio can be expressed in different formats, such as a decimal, fraction, or as a ratio. The choice of representation depends on the specific requirements and conventions of the gear drive application.

Additionally, it’s worth mentioning that gear drives can have multiple gears arranged in series or parallel, forming gear trains. In such cases, the overall gear ratio is calculated by multiplying the individual gear ratios of each gear pair in the train.

When designing or selecting gear drives, calculating the gear ratio is essential for determining the speed reduction or increase and torque amplification provided by the gear system. It enables engineers and designers to match the gear drive to the desired operational requirements of the mechanical system.

editor by Dream 2024-05-16

China high quality Harmonic Gearbox Gear Drive Hmcg-I with high quality

Product Description

Product Description

Introducing the HMCG-I Series Harmonic Reducer

Get ready to revolutionize your high precision applications with the HMCG-I series harmonic reducer from HangZhou Yijiaang Automation Technology Co., Ltd! This incredible gearbox is designed to take your aerospace, robotics, semiconductors, power inspection, and automation equipment to new heights.

Experience the Power of Harmonic Gear Transmission

Discover the cutting-edge transmission mode invented by American inventor C.W.Musser in 1955. The HMCG-I series utilizes the elastic deformation of flexible working components to achieve movement and power transmission like never before. Say goodbye to traditional rigid components and embrace the flexibility that brings a whole new level of functionality to your applications.

Unleash the Deceleration Principle

With the HMCG-I series harmonic reducer, you can harness the power of the deceleration principle. Watch as the flexwheel, rigid wheel, and wave generator work together in perfect harmony to achieve seamless motion and power transmission. The innovative design ensures that the flexwheel constantly deforms, resulting in precise and efficient movement transmission.

Product Specifications

- Product Name: Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer

- Applicable Industries: Machinery, Agricultural Machinery, Car, Robot

- Hardened Tooth Surface: Yes

- Installation Type: Horizontal Type

Don’t miss out on the opportunity to enhance your applications with the HMCG-I series harmonic reducer. Upgrade to the future of precision and efficiency today!

Product Parameters

| Model | Reduction ratio | Rated torque at input 2000r/min |

Permissible CHINAMFG torque at start/stop | Permissible max.value of ave.load torque | instantaneous permissible max.torque | Permssibie max.input rotational speed | Permissible ave.input rotational speed | Backlash (arc sec) | Transmission accuracy(arc sec) |

| Nm | Nm | Nm | Nm | r/min | r/min | ≤ | ≤ | ||

| 14 | 50 | 7 | 23 | 9 | 46 | 8000 | 3500 | 20 | 90 |

| 80 | 10 | 30 | 14 | 51 | 20 | 90 | |||

| 100 | 10 | 36 | 14 | 70 | 10 | 90 | |||

| 17 | 50 | 21 | 44 | 34 | 91 | 7000 | 3500 | 20 | 90 |

| 80 | 29 | 56 | 35 | 113 | 20 | 90 | |||

| 100 | 31 | 70 | 51 | 143 | 10 | 90 | |||

| 20 | 50 | 33 | 73 | 44 | 127 | 6000 | 3500 | 20 | 60 |

| 80 | 44 | 96 | 61 | 165 | 20 | 60 | |||

| 100 | 52 | 107 | 64 | 191 | 10 | 60 | |||

| 120 | 52 | 113 | 64 | 161 | 10 | 60 | |||

| 25 | 50 | 51 | 127 | 72 | 242 | 5500 | 3500 | 20 | 60 |

| 80 | 82 | 178 | 113 | 332 | 20 | 60 | |||

| 100 | 87 | 204 | 140 | 369 | 10 | 60 | |||

| 120 | 87 | 217 | 140 | 395 | 10 | 60 | |||

| 32 | 50 | 99 | 281 | 140 | 497 | 4500 | 3500 | 20 | 60 |

| 80 | 153 | 395 | 217 | 738 | 10 | 60 | |||

| 100 | 178 | 433 | 281 | 841 | 10 | 60 | |||

| 120 | 178 | 459 | 281 | 892 | 10 | 60 | |||

| 40 | 50 | 178 | 523 | 255 | 892 | 4000 | 3000 | 10 | 60 |

| 80 | 268 | 675 | 369 | 1270 | 10 | 60 | |||

| 100 | 345 | 738 | 484 | 1400 | 10 | 60 | |||

| 120 | 382 | 802 | 586 | 1530 | 10 | 60 |

Company Profile

Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer

Introducing the Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer

Upgrade your machinery with the state-of-the-art technology of the Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer from HangZhou Yijiaang Automation Technology Co., Ltd. This innovative product is engineered to elevate your transmission components, delivering unparalleled performance and reliability.

Equipped with a hardened tooth surface, this precision reducer ensures exceptional durability and longevity, making it ideal for various applications such as machinery, agricultural equipment, automobiles, and robotics. Its horizontal installation design facilitates seamless integration into your current systems, saving you time and effort.

Experience the superior speed reduction capabilities of this ultra-thin harmonic reducer. Its advanced gearbox technology guarantees smooth and precise operation, enabling flawless performance in CNC machine tools, packaging machinery, printing equipment, automation systems, collaborative robots, medical devices, AGVs, and more.

At HangZhou Yijiaang Automation Technology Co., Ltd, we are dedicated to delivering top-quality products and services. Our team of experts is committed to technological advancement and customer satisfaction, ensuring you receive an exceptional experience.

Don’t miss the chance to enhance your machinery with the Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer. Join us in propelling the world CHINAMFG and achieving new levels of efficiency and productivity. Contact us today!

Detailed Photos

FAQ

Introducing the Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer

Are you in need of a top-notch gearbox/speed reducer for your machinery, agricultural equipment, car, or robot? Look no further! HangZhou Yijiaang Automation Technology Co., Ltd has the perfect solution for you – our Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer.

With a hardened tooth surface, this reducer is built to withstand even the toughest conditions. Its horizontal installation makes it easy to integrate into your existing setup.

When choosing a gearbox/speed reducer, it’s important to provide the necessary information to ensure the perfect fit. You can start by providing the motor drawing with parameters, and our expert engineers will recommend the most suitable gearbox model for your reference. Alternatively, you can provide the following specifications:

- Type, model, and torque

- Ratio or output speed

- Working condition and connection method

- Input mode and input speed

By providing these details, you can rest assured that you’ll receive a gearbox/speed reducer that meets your exact requirements.

Don’t miss out on the opportunity to enhance the performance of your machinery with our Industrial Robot Ultra-Thin Series Hmcg Harmonic Precision Reducer. Get in touch with us today and experience the difference!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery, Car, Robot |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the best practices for troubleshooting common issues in gear drives?

Troubleshooting common issues in gear drives requires a systematic approach and adherence to best practices. Here’s a detailed explanation:

1. Gather Information:

– Start by gathering relevant information about the gear drive system, including its design specifications, operating conditions, and any recent changes or incidents.

– Consult equipment manuals, maintenance records, and any available documentation to understand the gear drive’s expected performance and maintenance requirements.

2. Visual Inspection:

– Perform a visual inspection of the gear drive to identify any obvious signs of damage, wear, or misalignment.

– Look for issues such as broken or chipped gear teeth, oil leaks, loose fasteners, or abnormal vibrations.

– Inspect lubrication levels and quality to ensure proper lubrication is maintained.

3. Measurement and Monitoring:

– Use appropriate measurement tools, such as vibration analyzers, temperature sensors, or lubricant analysis equipment, to gather quantitative data about the gear drive’s performance.

– Monitor variables such as vibration levels, temperature, noise, and oil condition to identify deviations from normal operating parameters.

4. Compare with Baseline Data:

– Compare the measured data with baseline or historical data to determine if there have been any significant changes or trends.

– Deviations from baseline data can indicate potential issues or abnormal wear patterns.

5. Consult Manufacturer Guidelines:

– Refer to the manufacturer’s guidelines, specifications, and troubleshooting manuals specific to the gear drive model or type.

– Follow the recommended procedures for troubleshooting and maintenance provided by the manufacturer.

– Manufacturers often provide valuable insights into common issues and their solutions for their gear drives.

6. Analyze and Identify Root Causes:

– Analyze the gathered information and data to identify the root causes of the issues.

– Consider factors such as overload conditions, misalignment, insufficient lubrication, gear wear, or inadequate maintenance practices.

– It may be necessary to engage the expertise of mechanical engineers, lubrication specialists, or other relevant professionals to help in the analysis.

7. Plan and Execute Corrective Actions:

– Develop a plan for implementing corrective actions based on the identified root causes.

– This may involve steps such as realigning the gear drive, replacing damaged components, adjusting lubrication practices, or implementing preventive maintenance measures.

– Prioritize the actions based on the severity and impact of the issues.

8. Monitor and Evaluate:

– After implementing the corrective actions, closely monitor the gear drive’s performance to ensure the issues have been resolved.

– Continue to gather data, measure key parameters, and compare with baseline data to verify the effectiveness of the corrective actions.

– Evaluate the

What are the best practices for troubleshooting common issues in gear drives?

Troubleshooting common issues in gear drives requires a systematic approach and adherence to best practices. Here’s a detailed explanation:

1. Gather Information:

– Start by gathering relevant information about the gear drive system, including its design specifications, operating conditions, and any recent changes or incidents.

– Consult equipment manuals, maintenance records, and any available documentation to understand the gear drive’s expected performance and maintenance requirements.

2. Visual Inspection:

– Perform a visual inspection of the gear drive to identify any obvious signs of damage, wear, or misalignment.

– Look for issues such as broken or chipped gear teeth, oil leaks, loose fasteners, or abnormal vibrations.

– Inspect lubrication levels and quality to ensure proper lubrication is maintained.

3. Measurement and Monitoring:

– Use appropriate measurement tools, such as vibration analyzers, temperature sensors, or lubricant analysis equipment, to gather quantitative data about the gear drive’s performance.

– Monitor variables such as vibration levels, temperature, noise, and oil condition to identify deviations from normal operating parameters.

4. Compare with Baseline Data:

– Compare the measured data with baseline or historical data to determine if there have been any significant changes or trends.

– Deviations from baseline data can indicate potential issues or abnormal wear patterns.

5. Consult Manufacturer Guidelines:

– Refer to the manufacturer’s guidelines, specifications, and troubleshooting manuals specific to the gear drive model or type.

– Follow the recommended procedures for troubleshooting and maintenance provided by the manufacturer.

– Manufacturers often provide valuable insights into common issues and their solutions for their gear drives.

6. Analyze and Identify Root Causes:

– Analyze the gathered information and data to identify the root causes of the issues.

– Consider factors such as overload conditions, misalignment, insufficient lubrication, gear wear, or inadequate maintenance practices.

– It may be necessary to engage the expertise of mechanical engineers, lubrication specialists, or other relevant professionals to help in the analysis.

7. Plan and Execute Corrective Actions:

– Develop a plan for implementing corrective actions based on the identified root causes.

– This may involve steps such as realigning the gear drive, replacing damaged components, adjusting lubrication practices, or implementing preventive maintenance measures.

– Prioritize the actions based on the severity and impact of the issues.

8. Monitor and Evaluate:

– After implementing the corrective actions, closely monitor the gear drive’s performance to ensure the issues have been resolved.

– Continue to gather data, measure key parameters, and compare with baseline data to verify the effectiveness of the corrective actions.

– Evaluate the success of the troubleshooting process and identify any lessons learned for future maintenance and troubleshooting activities.

By following these best practices, maintenance personnel can effectively troubleshoot common issues in gear drives, minimize downtime, and optimize the performance and lifespan of the gear drive system.

What are the signs of wear and tear in gear drives?

Identifying signs of wear and tear in gear drives is crucial for timely maintenance and preventing further damage. Here’s a detailed explanation of the common signs indicating wear and tear in gear drives:

1. Abnormal Noise:

– Unusual or increased noise during gear drive operation, such as grinding, squealing, or knocking sounds, can indicate worn or damaged gears.

– Excessive noise may result from pitting, chipping, or misalignment of gear teeth, requiring immediate attention.

2. Vibration:

– Excessive vibration during gear drive operation can be a sign of misalignment, gear tooth wear, or bearing damage.

– Vibrations may cause additional stress on the gears and other components, leading to accelerated wear and potential failure.

3. Changes in Performance:

– Decreased efficiency, reduced power transmission, or changes in speed and torque output can indicate wear and tear in gear drives.

– Increased slippage or difficulty in engaging gears may be a result of worn gear teeth or insufficient lubrication.

4. Increased Operating Temperature:

– If the gear drive operates at a higher temperature than normal, it could indicate excessive friction due to wear or inadequate lubrication.

– Elevated temperatures can accelerate wear and affect the overall performance and lifespan of the gear drive.

5. Oil Analysis:

– Regular oil analysis can help identify wear particles, contaminants, and changes in lubricant properties that indicate gear drive wear and tear.

– Presence of metal shavings, discoloration, or unusual debris in the oil can suggest gear or bearing deterioration.

6. Visual Inspection:

– Visually inspect the gear teeth for signs of pitting, chipping, scoring, or uneven wear patterns.

– Check for signs of excessive backlash, misalignment, or damage to bearings, shafts, and seals.

– Any visible damage or irregularities indicate wear and tear that requires attention.

7. Increased Friction:

– Higher friction levels, resulting in increased energy consumption or overheating, can be indicative of worn gears or inadequate lubrication.

– Excessive friction can lead to accelerated wear and further damage to the gear drive components.

It is important to address these signs of wear and tear promptly to prevent further deterioration and potential failure of the gear drive. Regular inspection, maintenance, and lubrication practices can help identify and mitigate wear-related issues, ensuring optimal performance and longevity of the gear drive system.

What are the common applications of gear drives in industry?

Gear drives find widespread applications in various industries due to their ability to efficiently transmit power and control speed. Here’s a detailed explanation of the common applications of gear drives in industry:

1. Automotive Industry:

– Gear drives are extensively used in automotive applications, such as transmissions and differential drives.

– They enable speed reduction, torque multiplication, and efficient power transmission in vehicles.

– Gear drives in automobiles help control speed ranges, enable gear shifting, and deliver power to the wheels.

2. Industrial Machinery:

– Gear drives are widely employed in various industrial machinery, including conveyors, mixers, pumps, and machine tools.

– They provide speed reduction or increase, torque amplification, and precise speed control in industrial equipment.

– Gear drives ensure efficient power transmission, synchronization of rotating components, and reliable operation of machinery.

3. Robotics and Automation:

– Gear drives play a critical role in robotics and automated systems for precision motion control.

– They provide speed reduction, torque amplification, and accurate positioning in robotic arms, joints, and manipulators.

– Gear drives enable smooth and precise movement in automated assembly lines, CNC machines, and other robotic applications.

4. Aerospace and Aviation:

– Gear drives are utilized in aerospace and aviation applications, such as aircraft engines, landing gear systems, and control mechanisms.

– They facilitate power transmission, speed control, and torque conversion in aircraft components.

– Gear drives in aviation require lightweight and high-strength materials to meet the demands of aircraft performance.

5. Energy and Power Generation:

– Gear drives are employed in power generation applications, including wind turbines, hydroelectric turbines, and steam turbines.

– They enable speed reduction or increase to match the rotational speed requirements of generators and power transmission systems.

– Gear drives play a vital role in efficient energy conversion and transmission in renewable energy and conventional power plants.

6. Mining and Construction:

– Gear drives are utilized in heavy machinery used in mining, construction, and earthmoving operations.

– They enable power transmission, speed reduction, and torque amplification in excavators, bulldozers, and dump trucks.

– Gear drives in mining and construction machinery withstand high loads, shock, and harsh operating conditions.

These are just a few examples of the common applications of gear drives in industry. Gear drives are versatile and can be found in various other sectors like marine, agricultural machinery, material handling, and more. The specific design, material selection, and configuration of gear drives depend on the requirements of the application, including load capacity, speed range, torque demands, and environmental conditions.

editor by Dream 2024-05-16

China factory Ultra Flat Zero Backlash High Accuracy Harmonic Gear Drive for Robot Joint spiral bevel gear

Product Description

Product Description:

1.Flexspline is a hollow flanging standard cylinder structure.

2.There is a large-diameter hollow shaft hole in the middle of the cam of the wave generator. The internal design of the reducer has a support bearing.

3.It has a fully sealed structure and is easy to install. It is very suitable for the occasions where the wire needs to be threaded from the center of the reducer.

Advantages:

The first:High precision,high torque

The second:dedicated technical personnel can be on-the-go to provide design solutions

The third:Factory direct sales fine workmanship durable quality assurance

The fourth:Product quality issues have a one-year warranty time, can be returned for replacement or repair

Company profile:

HangZhou CHINAMFG Technology Co., Ltd. established in 2014, is committed to the R & D plant of high-precision transmission components. At present, the annual production capacity can reach 45000 sets of harmonic reducers. We firmly believe in quality first. All links from raw materials to finished products are strictly supervised and controlled, which provides a CHINAMFG foundation for product quality. Our products are sold all over the country and abroad.

The harmonic reducer and other high-precision transmission components were independently developed by the company. Our company spends 20% of its sales every year on the research and development of new technologies in the industry. There are 5 people in R & D.

Our advantage is as below:

1.7 years of marketing experience

2. 5-person R & D team to provide you with technical support

3. It is sold at home and abroad and exported to Turkey and Ireland

4. The product quality is guaranteed with a one-year warranty

5. Products can be customized

Strength factory:

Our plant has an entire campus The number of workshops is around 300 Whether it’s from the production of raw materials and the procurement of raw materials to the inspection of finished products, we’re doing it ourselves. There is a complete production system

HST-III Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 6.2 | 0.6 | 20.7 | 2.1 | 7.9 | 0.7 | 40.3 | 4.1 | 7000 | 3000 | ≤30 | 10000 |

| 80 | 9 | 0.9 | 27 | 2.7 | 12.7 | 1.3 | 54.1 | 5.5 | |||||

| 100 | 9 | 0.9 | 32 | 3.3 | 12.7 | 1.3 | 62.1 | 6.3 | |||||

| 17 | 50 | 18.4 | 1.9 | 39 | 4 | 29.9 | 3 | 80.5 | 8.2 | 6500 | 3000 | ≤30 | 15000 |

| 80 | 25.3 | 2.6 | 49.5 | 5 | 31 | 3.2 | 100.1 | 10.2 | |||||

| 100 | 27.6 | 2.8 | 62 | 6.3 | 45 | 4.6 | 124.2 | 12.7 | |||||

| 20 | 50 | 28.8 | 2.9 | 64.4 | 6.6 | 39 | 4 | 112.7 | 11.5 | 5600 | 3000 | ≤30 | 15000 |

| 80 | 39.1 | 4 | 85 | 8.8 | 54 | 5.5 | 146.1 | 14.9 | |||||

| 100 | 46 | 4.7 | 94.3 | 9.6 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 120 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 160 | 46 | 4.7 | 100 | 10.2 | 56 | 5.8 | 169.1 | 17.2 | |||||

| 25 | 50 | 44.9 | 4.6 | 113 | 11.5 | 63 | 6.5 | 213.9 | 21.8 | 4800 | 3000 | ≤30 | 15000 |

| 80 | 72.5 | 7.4 | 158 | 16.1 | 100 | 10.2 | 293.3 | 29.9 | |||||

| 100 | 77.1 | 7.9 | 181 | 18.4 | 124 | 12.7 | 326.6 | 33.3 | |||||

| 120 | 77.1 | 7.9 | 192 | 19.6 | 124 | 12.7 | 349.6 | 35.6 | |||||

| 32 | 50 | 87.4 | 8.9 | 248 | 25.3 | 124 | 12.7 | 439 | 44.8 | 4000 | 3000 | ≤30 | 15000 |

| 80 | 135.7 | 13.8 | 350 | 35.6 | 192 | 19.6 | 653 | 66.6 | |||||

| 100 | 157.6 | 16.1 | 383 | 39.1 | 248 | 25.3 | 744 | 75.9 | |||||

| 40 | 100 | 308 | 37.2 | 660 | 67 | 432 | 44 | 1232 | 126.7 | 4000 | 3000 | ≤30 | 15000 |

HSG Parameter:

| Model | Speed ratio | Enter the rated torque at 2000r/min | Allowed CHINAMFG torque at start stop | The allowable maximum of the average load torque | Maximum torque is allowed in an instant | Allow the maximum speed to be entered | Average input speed is allowed | Back gap | design life | ||||

| NM | kgfm | NM | kgfm | NM | kgfm | NM | kgfm | r / min | r / min | Arc sec | Hour | ||

| 14 | 50 | 7 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | ≤20 | 15000 |

| 80 | 10 | 1 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | ≤20 | 20000 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | ≤20 | 20000 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 7500 | 5600 | ≤20 | 20000 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 7000 | 4800 | ≤20 | 20000 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||

| 40 | 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | 5600 | 4000 | ≤20 | 20000 |

Exhibition:

Application case:

FQA:

Q: What should I provide when I choose gearbox/speed reducer?