Product Description

Jh Series Explosion-Proof Prop-Pulling Winch Introduction

Product Description

Introduction of Jh Series Explosion-Proof Prop-Pulling Winch Introduction

Jh Series Explosion-Proof Prop-Pulling Winch JH series winches, explosion-proof, are mainly for underground prop pulling, transportation, and chute shifting.

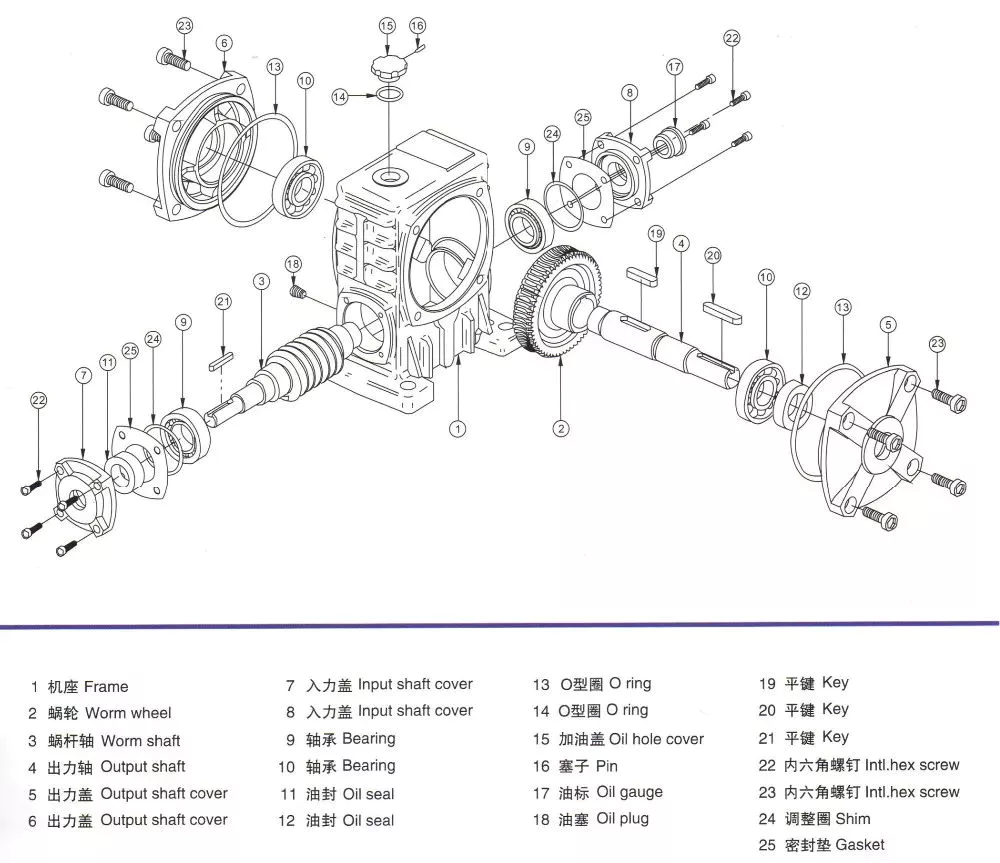

JH series winches, adopting the spherical worm gear pair drive, are compact and small and can be completely down the mine; the winches are symmetrically and rectangle arranged with the sledge-shaped chassis, smooth and flexible for underground self-moving; they are for both prop pulling and placing ground anchor due to low center of gravity and good features of chassis, so they are easy to install, smooth to operate, and safe and reliable. zmwm20

Product Parameters

Parameter of Jh Series Explosion-Proof Prop-Pulling Winch

| Model | JH-5 | JH-8 | JH-14 | JH-20 | JH-30 |

| Traction (KN) | 50 | 80 | 140 | 200 | 300 |

| Rope speed (m/s) | 0.17 | 0.09 | 0.094 | 0.1 | 0.13 |

| Rope diameter (mm) | 16 | 17 | 22 | 26 | 31 |

| Rope capacity(m) | 80 | 100 | 130 | 170 | 220 |

| Electric power (kw) | 7.5 | 11 | 18.5 | 22 | 45 |

| Overall dimensions (mm) | 1450×512×515 | 1600×530×670 | 2050×680×915 | 2200×968×864 | 3300×1075×1034 |

| Machine weight (kg) | 630 | 630 | 1350 | 2500 | 4460 |

ZheJiang CHINAMFG Industrial & Mining Supplies Group Co.,Ltd (hereinafter referred to as China Coal) is a group company, which is a collection of e-commerce, machinery manufacturing, software, research and development, modern logistics of large diversified industrial group. The group has 100 million yuan registered capital , with more than 1100 employees.

CHINAMFG is a professional manufacturing base of mines support equipment, transport equipment, lifting equipment, spray equipment, drilling equipment, ventilation equipment, lifting equipment and other products, as well as research and development new product and mine construction products with advanced high technology.

Detailed Photos

Photos of Jh Series Explosion-Proof Prop-Pulling Winch

Company Profile

Contact Us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Video or Technical Support |

|---|---|

| Warranty: | 1 Year |

| Type: | Electric Winch |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the environmental considerations in the manufacturing and disposal of gear drives?

Manufacturing and disposal of gear drives have environmental implications that should be taken into account. Here’s a detailed explanation of the environmental considerations associated with these processes:

Manufacturing:

-

Raw Material Extraction:

– The extraction of raw materials, such as metal ores and petroleum-based products, for gear drive manufacturing can have environmental impacts.

– Mining activities can cause habitat destruction, soil erosion, and water pollution.

– The extraction and processing of petroleum-based products contribute to greenhouse gas emissions and can lead to oil spills and other environmental disasters.

-

Energy Consumption:

– The manufacturing process of gear drives typically requires significant energy consumption.

– Energy-intensive processes, such as machining, casting, forging, and heat treatment, contribute to greenhouse gas emissions and air pollution.

– Manufacturers should strive to optimize energy efficiency, use renewable energy sources, and implement energy management practices to minimize the environmental impact.

-

Waste Generation:

– Gear drive manufacturing can generate various types of waste, including metal shavings, coolant and lubricant waste, and packaging materials.

– Improper disposal of these wastes can lead to soil and water contamination.

– Manufacturers should implement waste management practices, such as recycling, reusing, or properly treating and disposing of waste materials, to minimize their environmental impact.

-

Chemical Usage:

– Chemicals, such as lubricants, cleaning agents, and coatings, are often used in the manufacturing process of gear drives.

– Improper handling, storage, or disposal of these chemicals can be harmful to the environment and human health.

– Manufacturers should adhere to proper chemical management practices, including the use of environmentally friendly alternatives, safe storage, and responsible disposal.

Disposal:

-

End-of-Life Management:

– Gear drives eventually reach the end of their useful life and require proper disposal or recycling.

– Improper disposal can lead to the accumulation of gear drives in landfills, resulting in the wastage of valuable materials and potential environmental contamination.

– Manufacturers should encourage the return or collection of used gear drives for recycling or proper disposal.

-

Recycling:

– Recycling gear drives helps recover valuable materials and reduces the demand for new raw materials.

– However, gear drives can be complex assemblies with various materials, making recycling challenging.

– Proper dismantling and separation of materials are necessary for effective recycling.

– Manufacturers should explore design strategies that facilitate disassembly and recycling, such as using recyclable materials and minimizing the use of hazardous substances.

-

E-Waste Regulations:

– In some regions, gear drives may fall under electronic waste (e-waste) regulations due to their electronic components.

– Manufacturers should comply with applicable e-waste regulations, which often require responsible disposal and recycling of electronic components.

– This ensures that hazardous substances are managed properly and valuable materials are recovered.

By considering these environmental aspects in the manufacturing and disposal of gear drives, manufacturers can strive to minimize the environmental impact, promote sustainability, and meet regulatory requirements.

How do gear drives contribute to energy efficiency?

Gear drives play a significant role in improving energy efficiency in various mechanical systems. Here’s a detailed explanation of how gear drives contribute to energy efficiency:

1. Power Transmission:

– Gear drives efficiently transmit power from the input source to the output, allowing for effective energy transfer.

– They can handle high torque and transmit power over long distances with minimal energy loss.

2. Mechanical Advantage:

– Gear drives provide mechanical advantage by altering the speed and torque of the power transmission.

– By using different gear ratios, gear drives can match the mechanical requirements of the load, optimizing energy usage.

3. Efficiency of Gear Teeth:

– Well-designed and properly lubricated gear teeth can achieve high levels of efficiency.

– Modern gear drives are manufactured with precision to minimize friction and maximize power transmission efficiency.

4. Multiple Stages:

– Gear drives can be configured with multiple stages, each with different gear ratios.

– By dividing the total gear reduction into multiple stages, each stage can operate at a higher efficiency, resulting in improved overall energy efficiency.

5. Lubrication:

– Proper lubrication of gear drives reduces friction between the gear teeth, minimizing energy losses due to heat and wear.

– High-quality lubricants with appropriate viscosity and additives can enhance gear drive efficiency and extend their lifespan.

6. Maintenance:

– Regular maintenance practices, such as gear inspection, lubricant monitoring, and alignment checks, contribute to sustained energy efficiency.

– Timely identification and resolution of issues, such as misalignment or worn gears, help maintain optimal gear drive performance.

7. Design Optimization:

– Gear drives can be optimized for specific applications to maximize energy efficiency.

– Factors such as gear material selection, gear tooth profile design, and bearing choices can be tailored to minimize energy losses and improve overall efficiency.

By leveraging the inherent mechanical advantages and optimizing design and maintenance practices, gear drives significantly contribute to energy efficiency in various mechanical systems. Their ability to efficiently transmit power, adapt to different load requirements, and minimize energy losses through proper lubrication and maintenance make them a reliable and energy-efficient choice for power transmission applications.

How do you maintain and lubricate gear drives?

Maintaining and lubricating gear drives properly is essential for their smooth operation, longevity, and prevention of premature failure. Here’s a detailed explanation of the maintenance and lubrication practices for gear drives:

1. Inspection and Cleaning:

– Regularly inspect the gear drive for any signs of wear, damage, misalignment, or contamination.

– Clean the gear drive components, including gears, shafts, bearings, and housings, to remove debris, dirt, and old lubricant.

2. Lubrication:

– Select an appropriate lubricant based on the gear drive design, load capacity, operating speed, and ambient conditions.

– Follow the manufacturer’s recommendations for lubricant type, viscosity, and change intervals.

– Apply the lubricant evenly to the gear teeth, shafts, and bearings to ensure proper lubrication and minimize friction.

– Monitor the lubricant level and replenish or change it as needed to maintain optimal lubrication conditions.

3. Temperature Monitoring:

– Monitor the operating temperature of the gear drive using temperature sensors or thermal imaging devices.

– Excessive heat can indicate inadequate lubrication, overloading, misalignment, or other issues that need attention.

– Take corrective measures if the temperature exceeds the recommended range to prevent damage and ensure proper lubrication.

4. Alignment and Adjustment:

– Check and correct gear drive alignment regularly to ensure proper meshing and minimize wear.

– Adjust the gear drive components, such as bearings and shafts, as per the manufacturer’s specifications.

– Misalignment can lead to increased friction, premature wear, and reduced gear drive efficiency.

5. Vibration Analysis:

– Monitor the gear drive for abnormal vibrations using vibration analysis techniques.

– Excessive vibrations can indicate issues like gear tooth damage, bearing failure, or misalignment.

– Address any abnormal vibrations promptly to prevent further damage and maintain smooth operation.

6. Regular Maintenance Schedule:

– Establish a maintenance schedule and adhere to it to ensure consistent and timely gear drive maintenance.

– Include tasks such as lubricant checks and changes, inspections, alignments, and other maintenance activities.

– Keep records of maintenance activities, including lubricant changes, inspections, and repairs, for future reference.

By following these maintenance and lubrication practices, gear drives can operate efficiently, minimize wear and tear, and have a longer service life. It is important to refer to the manufacturer’s guidelines and consult with experts when performing maintenance on specific gear drive systems to ensure proper care and optimal performance.

editor by Dream 2024-05-02